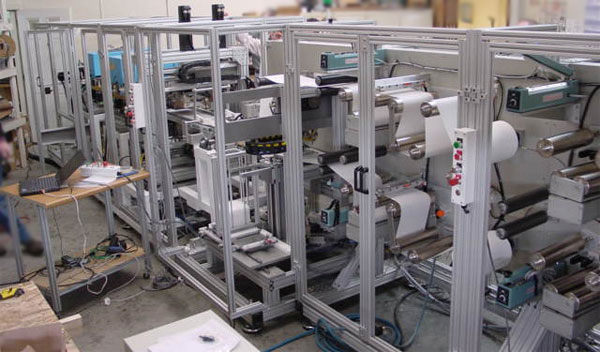

Automated Filter Machine for the Pharmaceutical Industry

Using its expansive engineering and fabrication resources, Mass Automation Corporation created an advanced; computer automated manufacturing system for the production of industrial filters. Our ability to bring a project from start to finish through one single provider enabled a fast turnaround time and excellent quality control.

We were tasked with supplying an automated filter production system, consisting of an unwinding phase, a sealing phase, and a cutting and placement phase. The completed system needed be compatible with an existing Selective Compliance Articulated Robot Arm production system. Our conceptual work included electrical and mechanical layout and design work, along with control programming and wiring. On-site metal fabrication and subsequent parts machining constituted our manufacturing of the filter machine, along with powder coating, assembly, and anodization. We used steel tubing and cast jig plate for our materials.

Follow-up factory acceptance and functionality testing validated both the quality of our work and compliance with customer needs. Thanks to our centralized approach to the project, a robust and high performance filter production system was delivered and installed in less than 15 weeks.

Mass Automation remains committed to delivering advanced automated equipment solutions for manufacturing needs. Customers can expect delivery windows of 12-14 weeks on similar projects. Contact us to learn more.

AUTOMATED FILTER MACHINE PROJECT HIGHLIGHTS

| Product Name | Automated Filter Machine | |

| Project Scope | To supply an automated filter production system consisting of three modules, a unwind section, a sealing section and a cutting and placement section. The complete system will interface with a fully automated SCARA filter assembly unit. | |

| Capabilities Applied/Processes | Primary:

| Secondary:

|

| Material Used | Steel Tubing Cast Jig Plate |

|

| In process testing/inspection performed | Factory Acceptance Test (FAT), Functionality Testing | |

| Delivery Time | 12 – 14 Weeks | |

| Standards Met | Customer Specifications, CAD Drawings | |